Picking

The Picking System is designed to revolutionize your warehouse and distribution operations, boosting productivity and efficiency. By integrating the Quick Picking System (QPS) with high-speed sorting devices and advanced LG CNS algorithms, it offers fully customizable operations to fit your needs. Smart Gantry and Auto Picking System automation optimize storage, picking, and inspection, while DPS/DAS digital systems guide your team with indicator-based instructions, eliminating the need for paper-based orders and ensuring fast, error-free operations.

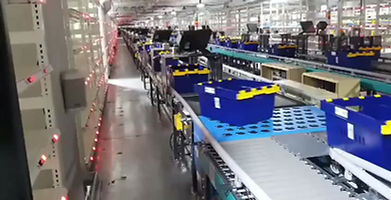

QPS (Quick Picking System)

QPS is an advanced picking and sorting solution designed to boost productivity. By integrating DPS, DAS, and high-speed diverting devices, it streamlines your operations with precision. Powered by LG CNS’s optimization algorithm, QPS offers customizable configurations tailored to your unique environment and needs. Plus, it easily connects with replenishment and sortation systems for a seamless, efficient workflow.

Key Features

-

Divided into picking station and bypass lines to secure high continuity of picking work

-

Productivity can be maximized through high-speed sorting & merging

-

Algorithm-based seamless operation to minimize workstation congestion

-

Real-time order allocation optimization to equalize workload and improve overall flow productivity

-

Improvement of worker productivity with a structure that puts only designated products into the target tote

Key Case

E Company

By applying the Quick Picking System, which minimizes productivity decline factors through the implementation of LG CNS's developed workstation load balancing and batch optimization algorithms, we have maximized picking productivity.

Smart Gantry

LG Smart Gantry is an AI-powered solution that transforms material handling in warehouses and manufacturing facilities. By combining advanced robotics with intelligent control, it optimizes storage, retrieval, and transportation, boosting efficiency while reducing labor dependency. This streamlined system helps improve overall operations and productivity, making it a game-changer for your logistics needs.

Key Features

-

Increased storage efficiency by direct loading without any supporting structure

-

By applying the Dual Picker, double picking in a single process is available

-

Rapid and accurate parcel handling and reduced processing time through an optimization algorithm

-

Easy expansion and relocation with a modular structure (various Picker models)

Key Case

M Company

LG CNS's world's first high-speed dual fork picker operates simultaneously or independently through an optimized algorithm, enabling fast picking and storage.

Auto Picking System

The LG CNS Auto Picking System automates the entire picking and inspection process, from start to finish. It features three key components: the A&V Frame for efficient product loading and automatic picking, the Pick Sort for semi-automatic picking of irregular products, and Vision Inspection for precise quality checks. Together, these devices create a fully optimized system tailored to meet your specific needs, boosting efficiency and accuracy across your operations.

Key Features

-

Increase work productivity by reducing the miss-picking rate through inspection automation

-

Tailored for various goods, multiple destinations, mass orders

-

Simple width adjustment of the replenishment rack enables easy product type change

-

Optimized configuration according to environment and conditions

-

Picking automation system replaces workers

Key Case

M Company

Medium and large items are picked using a V-Frame, while small items are picked using an A-Frame for automated picking. Additionally, a dual inspection process is performed automatically using vision technology for verification and a weight inspection system

DPS/DAS

DPS (Digital Picking System) enhances picking efficiency by using indicators at storage locations to guide item picking based on displayed quantities. It enables fast and accurate picking without paper-based orders.

DAS (Digital Assorting System) is an order fulfillment system that improves picking efficiency. Indicators on order cells guide the sorting of total-picked items from a tote into designated DAS cells.

Key Features

-

No paper list, use both hands freely

-

Shorter work time, no error

-

Items are picked based on the display of the indicator

-

Supporting an operator to perform accurately without knowledge of products

-

Increase work efficiency by changing locations as needed

Key Case

S Company

A DAS with a total of 17,000 indicators has been installed to guide the sorting of fully picked items from a tote into designated DAS cells.

Key Case

S Company

A DPS with a total of 12,800 indicators has been installed, supporting multi-item, high-frequency, and small-lot picking functions.